Resin castings

Resin is a material that is ideally suited for copying objects and for duplicating parts. It is easy to process and you can reach a high degree of detailing. These benefits make it quite popular for producing small series of scenery products. If you know how it works you can also make moulds and castings yourself. For example, the platform, the pavement, the relay switchboard and the points motor are all resin copies.

Before you can start casting anything, you have to make a mould first. Silicon rubber is well suited moulds which you can use for casts of resin or plaster. I use silicon rubber from Poly-Service, but there are also other suppliers. The material has two components. The rubber from the can is mixed with harder from small bottle. The proportion is 1:20 , therefore 95% per cent rubber and 5% harder. If you are going to the shop, you should buy some measuring cups. They make measuring the correct quantity a lot easier.

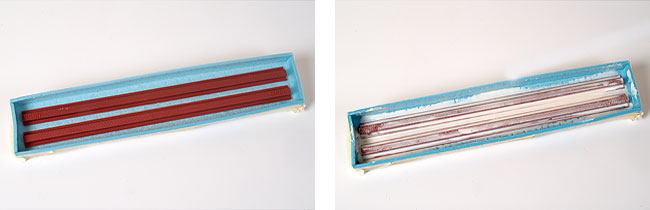

On the left is the original. In this case, wall parts of the chocolate factory which is on De Lage Zij. In the same way I have made platform sides and brick-paved roads. From left-over material you make a little tray that fits the original. The edges of the mould should be at least a half centimetre thick. The tray must a centimetre larger and a half centimetre taller than original.

The original is fixed on the bottom with double-sided tape or a few drops of superglue. It is now time to mix the silicon rubber. Before you poor the rubber into the tray, you have to cover the original with silicon rubber with an old brush. This will prevent air bubbles in the surface of your mould.

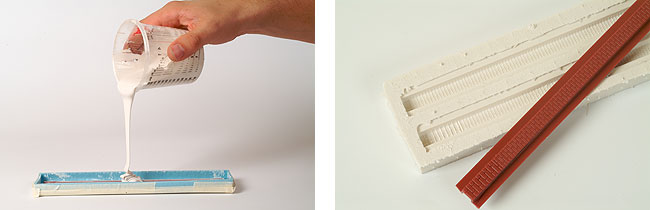

The tray is filled with silicon rubber. Pour the mixture in calmly and make sure that it is distributed evenly. Put the mould away for 24 hours in a warm place, for example on top of a heater. Do not clean your measuring cups right away. It is easier to let the rubber dry first. You can then pull it out of the cup. Take care that you do not get the rubber on your clothes. It will not come off with water or white spirit. The next day you can remove the tray. You now have your mould.

The moment has come to get the resin out. Besides resin you can use also use plaster to make casts. Plaster is nice if you plan to make a thick wall, but resin is much better for small or thin parts. The resin has two components, which are mixed 1:1. Calculate in advance how much you need. You have to work rapidly with resin. It settles in just a few minutes. After 30 minutes you can take the object out of the mould already. You can produce a lot of copies in a day if you want to.

The street in this photograph has been made with the same method. I just bought a small section of road and multiplied it many times. The road was painted in the correct colour with the airbrush. The seams were filled later with a coloured paste.

2006