Buitenlust moves on

May 2009. After moving to a temporary house first and to my new house a few months later, the time has finally come to start working on Buitenlust again. The story continues with building Baarn NCS station; you will find it at the bottom of the layout plan. The station is the part of the layout with most tracks and all those tracks will be laid nail after nail like the rest of the layout. It will take some time to finish this little job.

The station will be build on four segments. The fourth segment is curved to make the layout fit in the available room. It is also the biggest and heaviest segment. The fourth segment connects to the segments of the Vrolic factory. Like the Vrolic segments the new segments are made from 18 mm plywood. It is fairly heavy, but completely indestructable. And that might not be a bad idea given the weight and cost of the big O scale models. The segments are supported by specially constructed legs. The legs are about 100 cm in height. The lower support is intended for the future staging yard. The segments are tied together with big bolts.

The four segments fit exactly between the walls of the basement. The templates for the points have been glued in place and the tracks have been marked out. After the track has been laid, I will put up a backdrop along the wall. There will also be a lighting cove overhead.

The outline of the landscape is already visible. The spaces will be filled with styrofoam; that is really the fastest and easiest way to build a relatively flat landscape. Up next: sanding aand painting the sides of the segments.

Nail after nail

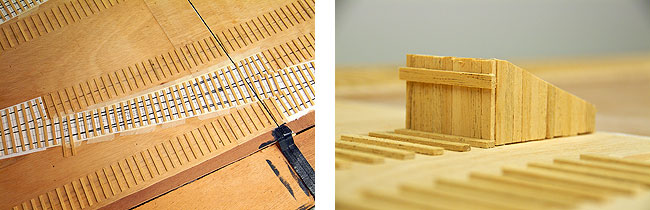

July 2009. It is a tremendous job, but the result is well worth it. All tracks are handlaid one nail at a time. For each meter of track that is about... a lot of nails. Unlike the previous layout sections, I am using the track from Wenz for the station of Baarn NCS. They just look better than the track from Hassler. However the track from Wenz is a lot more work to build. Especially the points are a major project. That is why I am using the track parts from Hassler for the points and I am combining them with ties and track plates from Wenz. The points look better, but they are still fairly easy to put together.

The tracks from Wenz and Hassler are based on the German and the Swiss prototype. Dutch tracks do look slightly different. Branchlines used to be outfitted with the so-called NP46 profile. The ties are further apart and the joints are not directly supported by double ties. I used old railroad manuals from the 1930's as a reference to adapt the points templates. The ties are in a different pattern and they are differently spaced.

The result comes pretty close to what a Dutch branchline looks like. This is typically the kind of track for short and light trains. As a bonus, you have to lay down less ties and that means less nails. The track plates from Wenz more or less look like the real NP46 parts and that also adds to the overall impression.

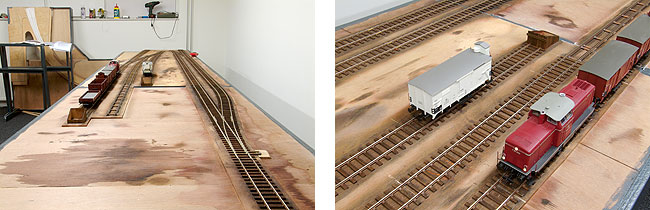

This where we are after two weeks of track-laying. The first three trunouts and the first two tracks are done. Like in real life, the tracks are not 100% straight (but the effect is exaggerated in this photo taken with a long lense). The V100 from Lenz (a German locomotive) is used here for testing purposes. It negotiates the track without any problems. Typical for Baarn NCS were these sand-filled buffer stops; they are recreated from old photographs.

Blood, sweat and a station

September 2009. The tracks of Baarn NCS station are taking shape. Three of the four segments have been done. Each meter of track has 59 sleepers, 118 rail chairs and 236 spikes. So that makes... many evenings of spiking tracks.

One day, the station building will appear in the foreground. You can also recognise the where the platform will be. The tracks to the left are goods tracks; the middle track will be part of the street.

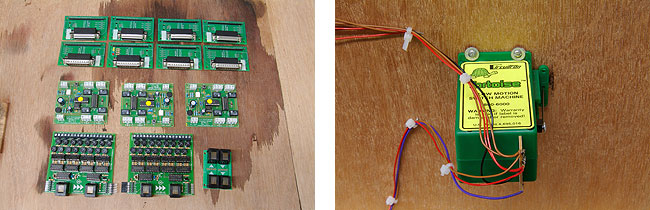

The electronics for the four segments. From top to bottom: module connectors, LDT accessory decoders and two BMD16N-SDs. The module connectors make it easier to connect the segments with standard computer cables. One of the segments will be the central segment and it will hold all the decoders. The other segments are to connected to that segment.

I use the trusted Tortoise switch machines to move the points. In O scale you have to replace the standard steal wire that comes with the Tortoise with a stronger 1.2 mm one. Points in O scale require a lot more force than H0 points.

The segments are put on their sides to do the wiring. The wires can easily be accessed and the wiring is done in no-time. This is one of the advantages of working with segments over a traditional fixed layout. All wires connect to the module connector in the bottom left corner.

I have screwed lathes against the wall to a have a basis to build on. The space between the laths was filled with more laths and covered with hardboard. The hardboard strips form the background of the layout and they have been painted matte blue. When the scenery is done I will paint a decent background on them.

The supports for the segments are fastened to the vertical laths with just a single screw. This prevents them from shifting. Over the layout will be a box construction with lights. The box will be suspended from the same vertical laths. Baarn NCS is already starting to look like a layout.

Step by step

November 2009. Buitenlust is steadily moving ahead. The big challenge of the last few weeks was eliminating the last flaws in the tracks. The points have been adjusted to meet the track standards and all joints have been smoothed out. I have connected the new sections to the old Vrolic modules. Trains like this little shunter can now move from the station of Baarn NCS to the Vrolic factory. The rest of the layout still has to be planned and build, but there is already a decent amount of track to play around with.

Next job: the platform edges of Baarn NCS. I made one master model and I copied it numerous times as resin castings. The casting were sanded and spray painted. The joints have been filled with a special gray paste. The photo with the carriage shows an impression of the final result. One day hopefully prototypical Dutch carriages will halt here instead of this German car.

The tedious process of ballasting has started. I still have to pick up several kilos of Anita Decor's sandstone ballast before I can complete therest of the station. The inspection paths alongside the track are made from Kalksteinsplitt from Asoa. The points are a combination of parts from Hassler and Wenz. I have also ordered some slide chairs from C+L finescale to improve a bit on the detailing.

Lets' go

December 2009. It may look like nothing much has been happening, but the opposite is true. The supporting construction for the Vrolic modules has been finished. All layout segments now have a backdrop and luminiscent lighting. So... time to move ahead and to build Buitenlust!

One corner mdoule was still missing on the left. Not any more. This module is the last module of the upper level; all subsequent modules will be about 30 cm lower. The sleepers have already been glued to the base board. After they have been painted, the tracks will be laid. Then the contours of the landscape will be added.

This is how Buitenlust looks at the moment. The corner module is missing in this picture and it will be added on the left The overhead construction holds the lights. It is covered with plastic to protect the layout from dust.

2009